With the help of my buddy Mike, we’ve been assembling a fresh motor for the 710. The car came with a usable race motor when I bought it, but now that the car chassis is coming around, it was time for a hi-spec, vintage-legal motor that I knew all the parts of. The ’74 710s came with a L20b engine, so that’s what we started with. The stock 85mm bore is allowed a vintage-legal 1mm overbore, so we’re using 86mm pop-up JE pistons in a fresh o-ringed block. Stock stroke is required, so we’ve got a lightened and knife-edged OE crank in use. We plan on revving the piss out of it so a fresh set of Carillo rods are in there too. A ported OE a87 cylinder head with 38cc chambers and a secret grind Rebello cam tops it off.

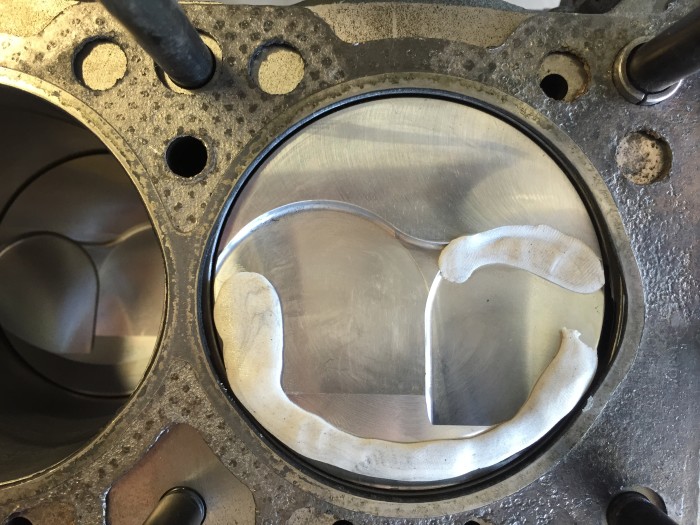

During assembly we encountered a few interference issues, so we dug out the die grinder and sanding drums. The 37mm exhaust valves were tickling the cylinder bore, so we needed to eyebrow the bore just a little. The high compression pistons were touching the edge of the cylinder head chamber, so we decided to remove a little material from the head instead of from the pistons. And while we were at it, we confirmed the valve-to-piston clearance was sufficient. Fresh bearings, rings, gaskets, etc, finish it all up. For those curious about the math, that’s 1.99 liters displacement, and a 13.0:1 compression ratio. Can’t wait to give it a try next week…

*** Added note – I f**#ked up the motor install, and hopefully you can learn from my mistake. As I installed the new motor, the oil system lines lined up as they did during disassembly. Unfortunately the oil sandwich plate clocked itself 180 degrees off on the new block compared to the old one, meaning my oil flow was now reversed. Yes, I missed that the lines now went to the wrong ports, arghh… Oil now left the block to the cooler instead of to the filter, thus causing oil flow to stop at the one-way check valve in the filter. I did not catch this error as the oil pressure gauge port is at the aux oil filter assembly, so I was reading full oil pressure on the gauge while little oil was returning to the block. I ran the motor for several minutes before it starting seizing up, cooking the crank bearings and scratching up a couple pistons and bores. Motor is back out now being inspected, an expensive and frustrating mistake indeed. Lesson learned – after first priming the oil system, always start the new motor with the oil cap off so you can make sure oil is making it all the way to the top of the system right away… ***

Mike Malone and I do my motor work. You’ll find Mike on most of the Datsun FB pages selling his Mikuni carb set-ups for Datsuns.

Nice engine work. May I ask who did the work ?